NZAI-EN-LNG-102

Regasification + LNG Tank Design + Throughput Understanding

This program provides participants with practical insights into LNG storage tank design and regasification systems, highlighting why these are mission-critical systems where design mistakes can lead to operational failures, higher cost, and reputational risks. This program trains you not only to learn the design fundamentals but also to understand the real consequences of poor design choices.

Secure your spot now — limited seats remaining!

Duration

2 Days

Full Remote (Live) or Face to Face in Thailand

Learn directly from practitioners — join live remote sessions or attend face-to-face programs in Thailand.

Advanced Level

Designed for professionals seeking deep, applied skills in Energy Transition, and LNG

Resources

Includes videos, diagrams, quizzes, and downloadable resources

Objective

This program provides participants with practical insights into LNG storage tank design and regasification systems, highlighting why these are mission-critical systems where design mistakes can lead to operational failures, higher cost, and reputational risks. This program trains you not only to learn the design fundamentals but also to understand the real consequences of poor design choices.

Detailed 2-Days Curriculum

Day 1 – LNG Storage: Foundations & Risks

- Why regasification and LNG tanks are becoming increasingly critical in today’s LNG supply chain.

- Global case references: how storage failures and poor tank design led to operational disruptions.

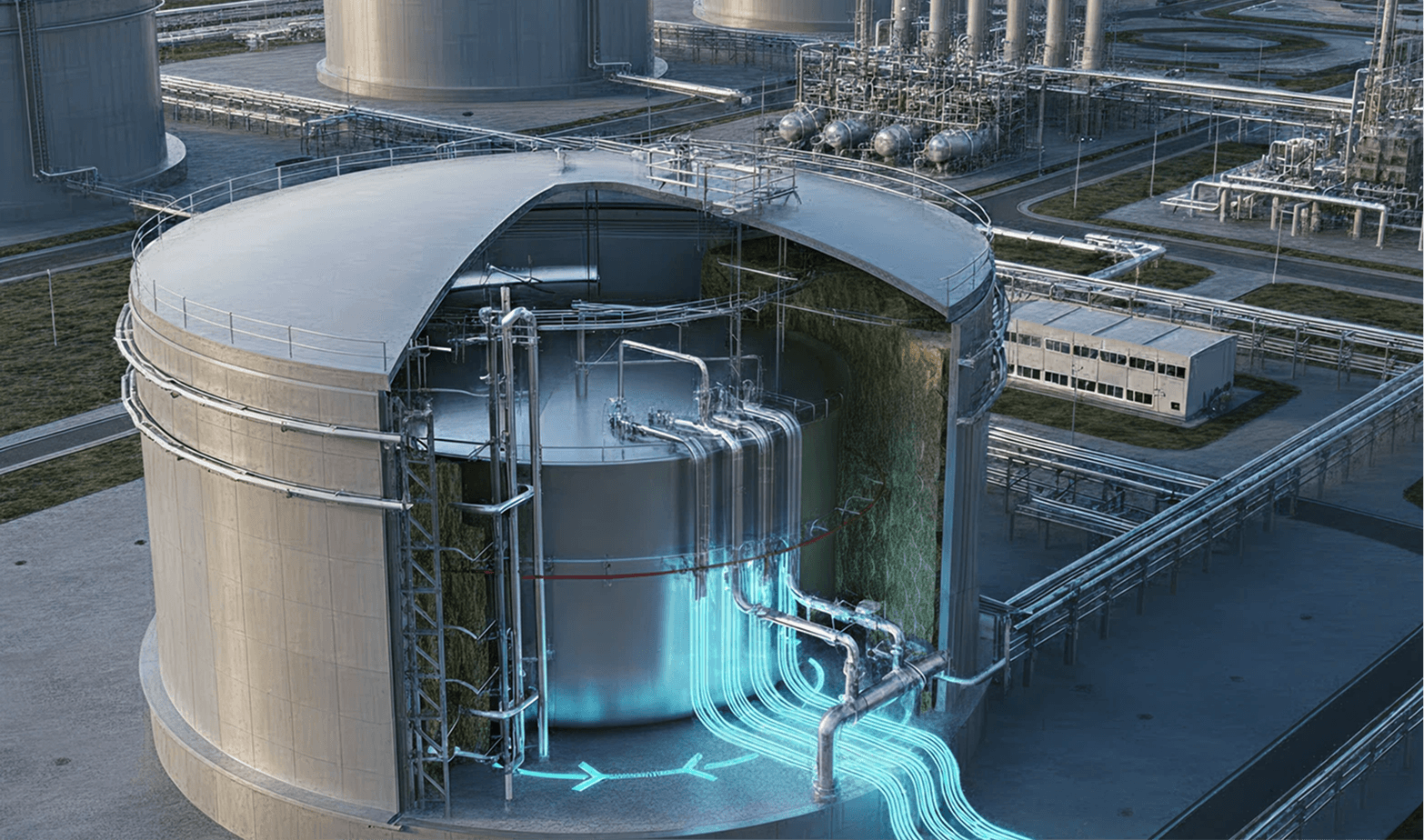

- LNG tank types (full containment, membrane, in-ground) and where each is suitable.

- Tank capacity measurement — and why wrong sizing leads to long-term project losses.

- Boil-off gas (BOG) management: what happens if it’s mishandled or underestimated?

- Tank design safety principles: insulation, rollover prevention, and redundancy.

Day 2 – Regasification Systems & Throughput Mastery

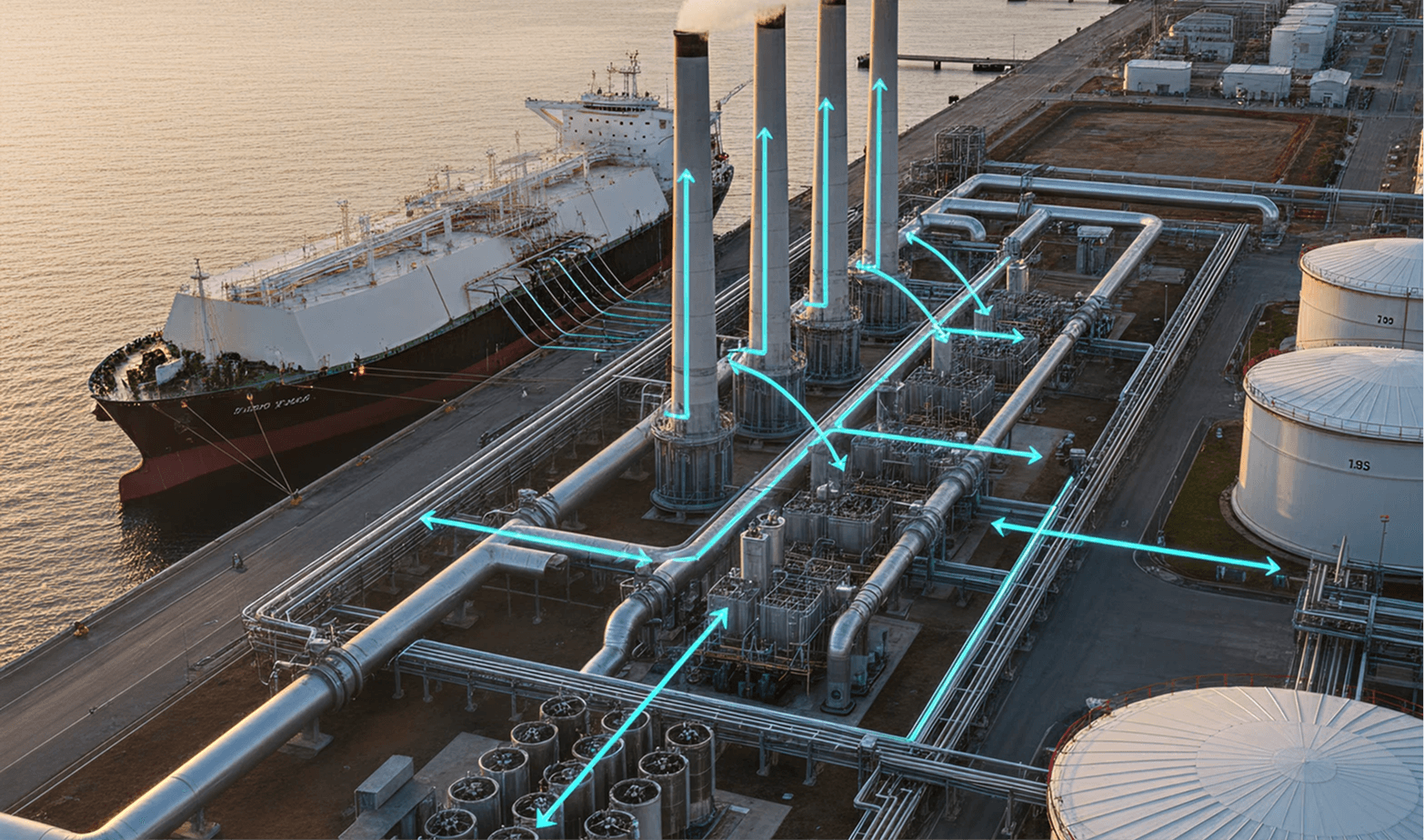

- The role of regasification in national energy security — why reliability matters more than ever.

- Regasification technologies (ORVs, SCVs, IFVs): benefits, risks, and when they fail.

- Send-out systems and pressure control — consequences of a design mismatch.

- Throughput & capacity calculations: annual vs peak demand, storage-turnover ratios.

- What goes wrong when throughput doesn’t match capacity? delays, demurrage, and financial exposure.

- Case studies: international examples of successful vs failed regasification designs.

- Group activity: Design throughput and send-out capacity for a sample LNG terminal and assess risks.

Mode of Delivery

The program is conducted in 2 days, offered either in remote live mode or through face-to-face discussions in Thailand.

What Will You Learn

By the end of this program, you will be able to:

- Explain why LNG tanks and regasification are high-risk systems in every import terminal.

- Identify hidden risks in tank sizing and send-out capacity.

- Perform throughput calculations and justify them with confidence.

- Assess different regasification technologies and their vulnerabilities.

- Apply consultant-level thinking: not just how to design, but how to defend decisions and highlight risks.

Practitioner Profile

Mr. Rishi Agrawal

This course is delivered by an LNG Expert with 15+ years of experience in:

- Designing and reviewing LNG import terminals, FSRUs, and FSUs.

- Leading LNG import terminal projects for global clients (Asia, the Middle East, Europe).

- Hands-on expertise in marine operations, topside safety, and LNG infrastructure planning.

Practitioners are recognized in the LNG industry, having advised on billion-dollar LNG-to-Power projects and regasification projects.